Welding and brazing

Our welding division covers a wide range of processes – from manual hand welding, spot welding, and stud welding to automated TIG welding with 8-axis robotic systems.

Automated TIG welding with 8-axis robot technology

Our welding cell is equipped with an 8-axis TIG welding robot. The system works with a zero-point clamping system, enables welding with or without filler material, and is equipped with two welding stations (180° rotary tables) – ideal for precise and repeatable series production.

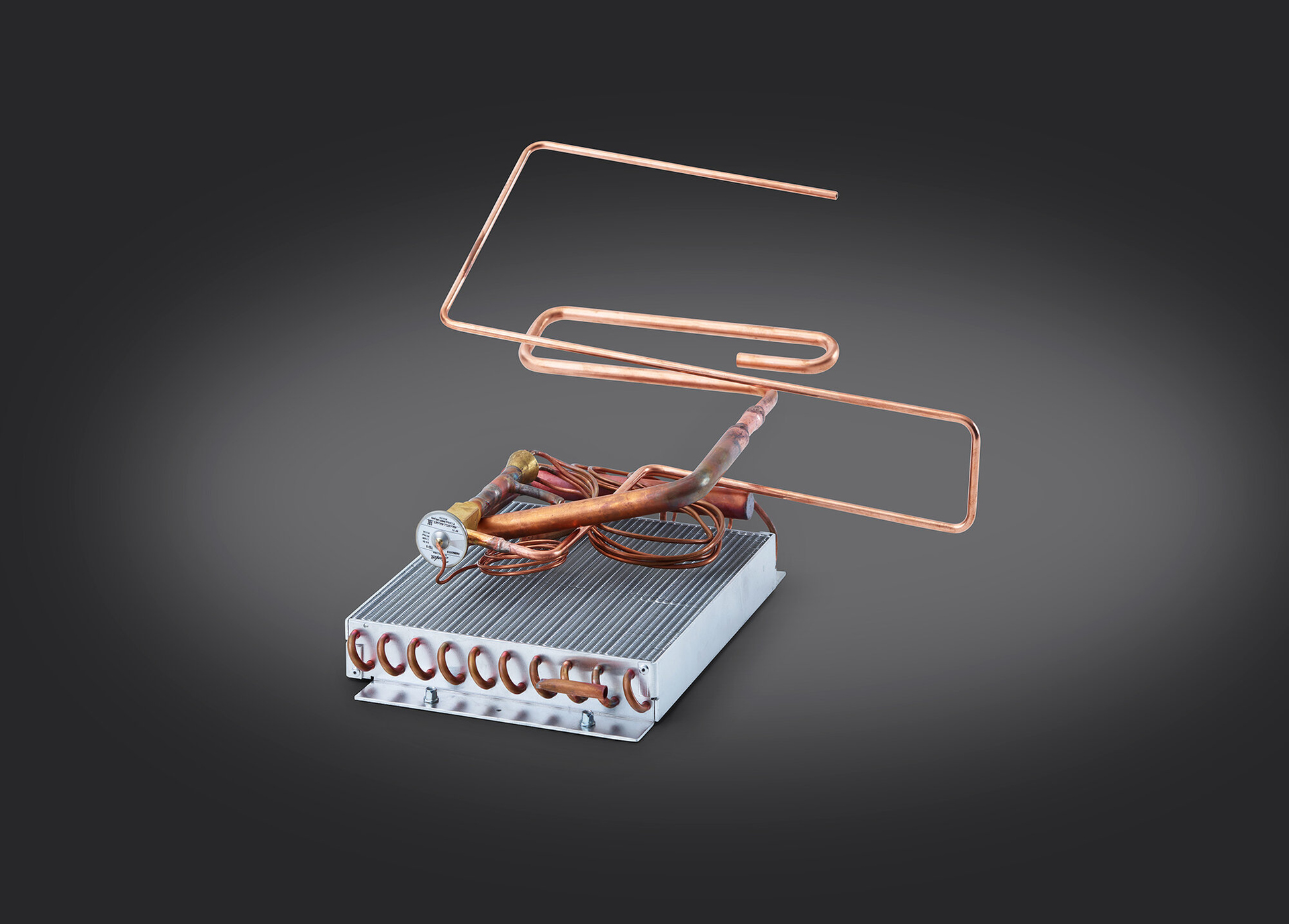

Brazing pipe joints

Our production facility creates high-quality, temperature-resistant brazed joints – ideal for applications in refrigeration and air conditioning technology as well as gas pipe installations. Depending on the material, we offer:

Copper to copper and copper to brass up to Ø 28 mm (with copper-phosphorus or silver solder)

Copper or brass to stainless steel or iron up to Ø 35 mm (with silver solder)

Equipped for serial brazing

In our production facility, we create high-quality, temperature-resistant brazed joints. Whether pipe systems or complex assemblies: we manufacture medium to large series using specialized equipment.

Our soldering shop has seven fully equipped workstations with:

- central gas supply

- modern soldering torches and extraction technology

- forming equipment

- equipment for leak testing assemblies